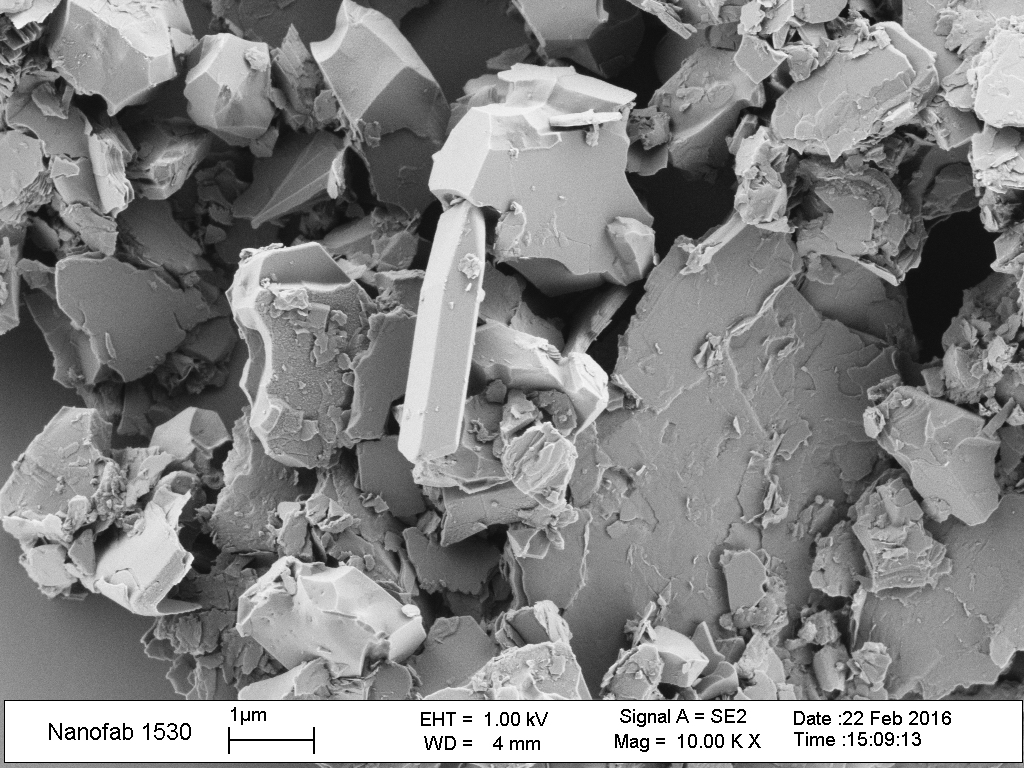

I decided to write this short addendum to “Does JNat slurry break down?” to address an ongoing misconception about the nature of the abrasive grit in Japanese finishing stones. Anyone who browses the internet on this topic is likely to find reference to the opinion that the abrasive in Japanese finishing stones (Toishi) consists of flake-like particles and that the separation of these into thinner flakes is the underlying mechanism of the so-called break-down of abrasive to finer grit. There can also be found some amateurish quality SEM images purporting to show the slurry from a Nakayama finishing stone before and after sharpening a razor.

In part 1 of this article it was shown that on a particular kamisori toishi razor hone, silica particles (radiolaria) were the abrasive component, not the flake-like structures (phyllosilicates). The phyllosilicates (clay) are the binding component of the stone. At the time, I did analyze a variety of stones and repeated the experiment a multitude of times, but for brevity reported only the one experiment with that single Toishi. The purpose of this article is to provide some additional evidence that the abrasive component of Japanese finishing stones is typically radiolaria silica.

Just over three years ago, Alex Gilmore (proprietor of thejapanstone.com) asked me if I would be interested in analyzing some samples of Japanese finishing stones after seeing some of my work on Coticule stones and slurry. Alex sent me a variety of samples, including the four shown below which, at the time, I experimented with and analyzed. Subsequent to that work, I performed the experiments which were summarized in part 1. For the images shown below, I revisited some of those stone samples and prepared slurries for imaging.

In each case, a slurry was formed using an Atoma 400 plate and deionized water. To minimize the possibility of cross-contamination, a thick slurry was formed and then the plate and stone were rinsed clean with DI water three times, and the fourth time the slurry was collected. Slurry was deposited on a clean, smooth surface and allowed to dry, and then imaged by SEM.

In all four cases, silica particles of approximately 3 microns are visible, dimensions and shapes typical of Radiolaria silica. These observations are entirely consistent with those discussed in part 1 of this article.

15 responses to “JNAT slurry – part 2”

Thanks for posting this! Did you look at edges while you were working the slurry, btw? While one guy and a couple of razors and hones do not a definitive study make, I’d be curious to see the near-apex refinement as the slurry gets worked (regardless of what the cause of slurry breakdown is).

LikeLike

The effect of slurry and natural stones is something I will cover in the future.

LikeLike

Just went through all the posts made on your blog. Just amazing information. Thank you for all the great work and for sharing all this!

Would love to read your post on “effect of slurry and natural stones” (especially JNATS). Really looking forward to reading you.

cheers

LikeLike

Also, did you start using a different SEM setup for this series of images?

LikeLike

Yes, I used my other microscope for this set of images.

LikeLike

I just wanted to point out that “JNAT slurry – part 2” isn’t visible on the home page.

LikeLike

Probably for the best, but I have added it now, thanks.

LikeLike

Haha

LikeLike

Seeing the mention of “my work on Coticule stones and slurry”, where can it be found? I have received ‘some’ coticule, therefore my interest.

The scienceofcharp avatar is maybe already a reference.

LikeLike

Unfortunately, most of that discussion was on a private forum.

LikeLike

Hi … I really appreciate your scientific approach and the neutral way of writing about this topic. Thanks for the efforts you spent. However: I would also kindly reask if there was a possibility to publish your work on coticule somehow, e.g. by asking the forum owner, so the efforts you made at that time can extend the knowledge provided in your blog?

LikeLike

Does a slurry actually sharpen an apex or does it convex and or chip out? ive read through every article you have posted and believe you might have touched base on it but its alot to absorb and dont remember your findings. reason i was asking was, ive been making a neatsfoot oil/diamond powder mix and using it as a slurry atop of sintered ceramic aluminum oxide stones that ive lapped with alot of mixed results. ive tried from 140 grit up to 100k but im not even sure what its doing to the apex with the cheap digital scope i have at least no where near the level of what your SEM images are creating obviously. After visiting your site for a year or two now its hard to surf the web and listen to “belief” of whats happening especially since you have released some truth in varying sharpening topics. Your discoveries have made me learn and question what everyone still pins as fact when they havent seen some of your data here.

LikeLike

Slurry or mud micro-chips the apex, so it prevents burr formation but also prevents the formation of a keen edge. The primary role of slurry is to add “3-body abrasion” to the mix, which will generally speed up steel removal by softening and roughening the outer micron or two of the steel. Essentially that 3-body damage is also what removes the last micron of the apex.

The keen, shaving edge that we create with natural stones seems to alway be a result of burnishing on silica inclusions in the stone. This burnishing action does leave a micro convex apex.

LikeLike

I heard one guy taking about 3 body abrasion(loose slurry) and how it slows the honing, and how it doesnt speed cutting, but this was in reference to synthetic waterstones. I think thats what he attributed the cluudy finish to, the dents and dings on the bevel.

I dont recall that he used anything bbesides theoretical physics and the naked eye to arrive at this point and im curious if there is any evidence that confirms this. I know When i use my 8k stone that a slip of angle(accidentally lowering it, scrstching above the bevel) leaves marks almost ike it was sandblasted with loose grit..

I also wonder if the slurry from the Jnats actually does cut, but shallower like loose grit on a strop?

LikeLike

It’s true that slurry on a Shapton Pro 320, for example, slows down grinding, while slurry on a Coticule, for example, speeds up grinding. In my experience, the loose slurry particles damage/soften the outer 1-2 microns of the metal making it “easier” for the fixed abrasive particles to penetrate and grind metal. My guess is that larger slurry particles float the blade away from the fixed particles (like ball bearings) and prevent scratching/grinding from occurring.

It’s more complicated that this though, because raising a slurry also roughens the stone surface, exposing fresh/sharp fixed grit particles that will also grind more efficiently.

And if that isn’t complicated enough, loose grit particles can become embedded in the softened steel, slowing down the grinding.

LikeLike